NiCrBSi nickel based self fluxing alloy powder

Keywords: nickel based self fluxing alloy powder, thermal spraying powder

Features: NiCrBSi is a kind of high hardness alloy powder, performance, wettability and autolysis of spraying powder, spray deposition layer corrosion resistance, abrasion resistance, wear resistance.

Purpose: it is suitable for automobile piston ring, air valve, sealing ring, piston and shaft.

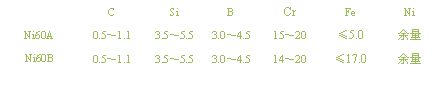

Chemical composition of NiCrBSi alloy powder wt%

Ni15 nickel based self fluxing alloy powder

Keywords: nickel base self fluxing powder, wear-resistant alloy powder, nickel powder spraying base

Features: Ni15 is the low hardness of nickel, boron, silicon, copper alloy powder, autolysis, better wettability and corrosion resistance, easy processing.

Uses: suitable for casting parts, mold and other defects repair.

Powder melting temperature: 1050 ~ 1150 degrees C

Hardness of spray deposited layer: HB150 ~ 180

The range of particle size: - 150 (one step).

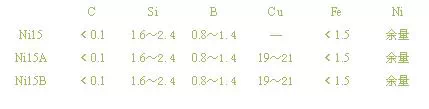

Chemical composition of Ni15 alloy powder wt%

Ni17 nickel based self fluxing alloy powder

Keywords: powder, nickel based alloy spraying wear-resistant autolysis

Features: Ni17 alloy powder with lower hardness, autolysis and spray welding performance of powder spray welding layer deposition are good corrosion resistance, easy forming.

Application: suitable for repairing glass mould, cast iron, machine tool, shaft, etc..

Powder melting temperature: 1050 ~ 1150

Hardness of spray deposited layer: HB170 ~ 210

The range of particle size: - 150 (one step).

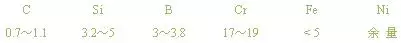

Chemical composition of Ni17 alloy powder wt%

Ni20 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolysis based alloy powder, nickel powder

Features: Ni20 is the lower hardness of the alloy powder, powder, autolysis of wetting and spray welding performance, spray deposited layer corrosion resistance, oxidation resistance, easy forming.

Application: suitable for surface strengthening and repairing of glass mould, cast iron, machine tool, shaft and so on.

Powder melting temperature: 1040 ~ 1100

Hardness of spray deposited layer: HRC17 ~ 23

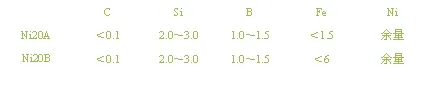

Chemical composition of Ni20 alloy powder wt%

Ni25 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear powder, autolysis of nickel based alloy powder

Features: Ni25 is the low hardness of the alloy powder, powder, autolysis of wetting and spray welding performance, spray deposited layer corrosion resistance, resistance to cold, heat resistance, easy processing etc..

Application: it is suitable for surface strengthening and repairing of glass, plastic, rubber, etc..

Powder melting temperature: 1050 ~ 1120

Hardness of spray deposited layer: HRC23 ~ 28

Powder size range: - 150 mesh, 320 mesh (one step), - 150 mesh + 320 mesh (Er Bufa)

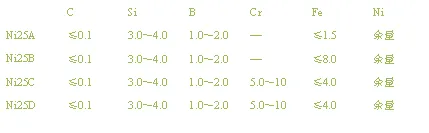

Chemical composition of Ni25 alloy powder wt%

Ni30 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, powder spraying, autolysis, wear resistance of nickel based alloy powder

Features: Ni30A alloy powder is moderate hardness, autolysis and wettability and good performance of spray welding and spray welding layer corrosion resistance and wear resistance and good toughness characteristics of powder.

Uses: suitable for mold, shaft, gas turbine blades, gear and other surface strengthening and repair.

Powder melting temperature: 1050 ~ 1120

Hardness of spray deposited layer: HRC28 ~ 32

Powder size range: - 320 mesh (one step), - 150 mesh + 320 mesh (Er Bufa)

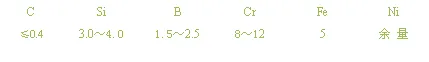

Chemical composition of Ni30A alloy powder wt%

Ni35 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolyzed powder, nickel base alloy powder

Features: Ni35 alloy powder is moderate hardness, performance, wettability and autolysis of spraying powder, corrosion resistance and wear resistance.

Application: suitable for surface strengthening and repair of shaft, punch, pull rod, valve, gear etc..

Powder melting temperature: 1020 ~ 1100

Hardness of spray deposited layer: HRC33 ~ 38

Powder particle size range: - 150 ~ +320 mesh (Er Bufa), - 320 mesh (one step)

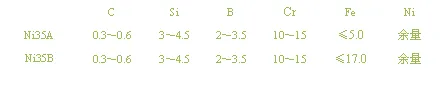

Chemical composition of Ni35 alloy powder wt%

Ni45 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolyzed powder, nickel base alloy powder

Note: Ni45 is the hardness of the alloy powder, powder, autolysis of wetting and spray welding performance, corrosion resistance, corrosion resistance and other characteristics.

Application: applicable to the oil and chemical industry valve, valve seat, pump, rotor, piston, rod, gear and other parts of the anti - wear, corrosion and repair.

Powder melting temperature: 980 ~ 1050

Hardness of spray deposited layer: HRC42 ~ 48

Powder particle size range: - 150 ~ +320 mesh (Er Bufa) - 320 mesh (one step)

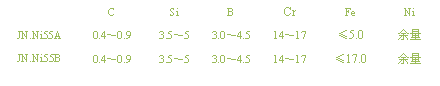

Chemical composition of Ni45 alloy powder wt%

Ni50 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolyzed powder, nickel base alloy powder

Features: Ni50 is a kind of high hardness alloy powder, powder, autolysis of wetting and spray welding performance, wear resistance, corrosion resistance, heat resistance and other characteristics.

Application: suitable for surface strengthening and repairing of oil filling, valve, shaft and other parts.

Powder melting temperature: 980 ~ 1050

Hardness of spray deposited layer: HRC:48 ~ 53

Powder particle size range: - 150 ~ +320 mesh (Er Bufa) - 320 mesh (one step)

Chemical composition of Ni50 alloy powder wt%

Ni55 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolyzed powder, nickel base alloy powder

Features: Ni50 is a kind of high hardness alloy powder, powder, autolysis of wetting and spray welding performance, hard wear and corrosion resistance, suitable for wet grinding cutting.

Application: suitable for surface strengthening and repairing of oil filling, valve, pump cover, shaft and other parts.

Powder melting temperature: 970 ~ 1070

Hardness of spray deposited layer: HRC:53 ~ 57

Powder particle size range: - 150 ~ +320 mesh (Er Bufa) - 320 mesh (one step)

Chemical composition of Ni55 alloy powder wt%

Ni60 nickel based self fluxing alloy powder

Keywords: nickel base alloy powder, spraying wear-resistant autolyzed powder, nickel base alloy powder

Features: the powder is of high hardness Ni-Cr-B-Si is one of the most widely used self fluxing alloy powder. Has excellent comprehensive performance, corrosion resistance, oxidation resistance, heat resistance, low stress wear and wear resistance and good impact toughness. Low melting point, solid liquid phase temperature range, a variety of matrix and WC particles, such as strong wetting ability, easy to operate. Ni60 is a kind of high hardness alloy powder, powder, autolysis of wetting and spray welding performance, hard wear and corrosion resistance, suitable for wet grinding cutting.

Application: suitable for surface strengthening and repairing of shaft, valve, plunger, sealing ring, conveying roller, pump cover, scraper and other parts.

Powder melting temperature: 950 ~ 1050

Hardness of spray deposited layer: HRC:58 ~ 63

Powder particle size range: - 150 ~ +320 mesh (Er Bufa) - 320 mesh (one step)

Chemical composition of Ni60 alloy powder wt%